Digitalization in the Plant Engineering Sector - LINGL4.0

Nov. 2018

Keywords such as “Industry 4.0“ or “Digitalization“ are frequently used in today’s society and in the media.

But what do these terms mean to us, the company Lingl, in the broadest sense?

The opportunity of digitalization for us is to call into question and analyze the traditional knowledge as well as to optimize it together with our customers for the purpose of achieving a sustainable competitive edge.

While doing this, Lingl not only acts as a plant engineering company but also as a strategic partner from consultancy and planning to the complete implementation of individual tasks.

Following the guiding principle “with tradition and innovation to smart production“ it is our declared objective to accompany our customers on their way to their “Smart Factory”.

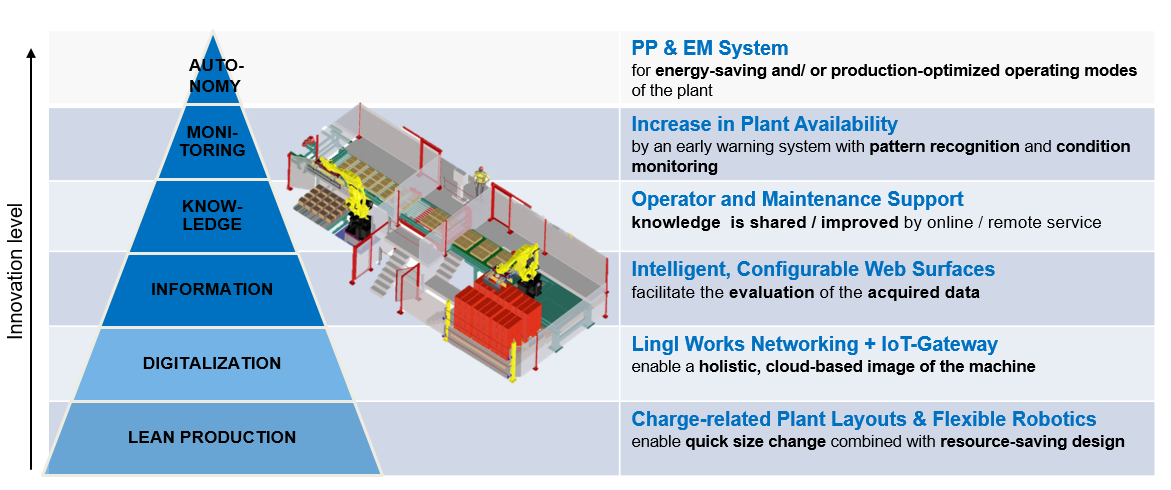

Adaptability, efficient use of resources and the melting of information, communication, automation and production technologies constitute the vital core of an intelligent, future-oriented production.

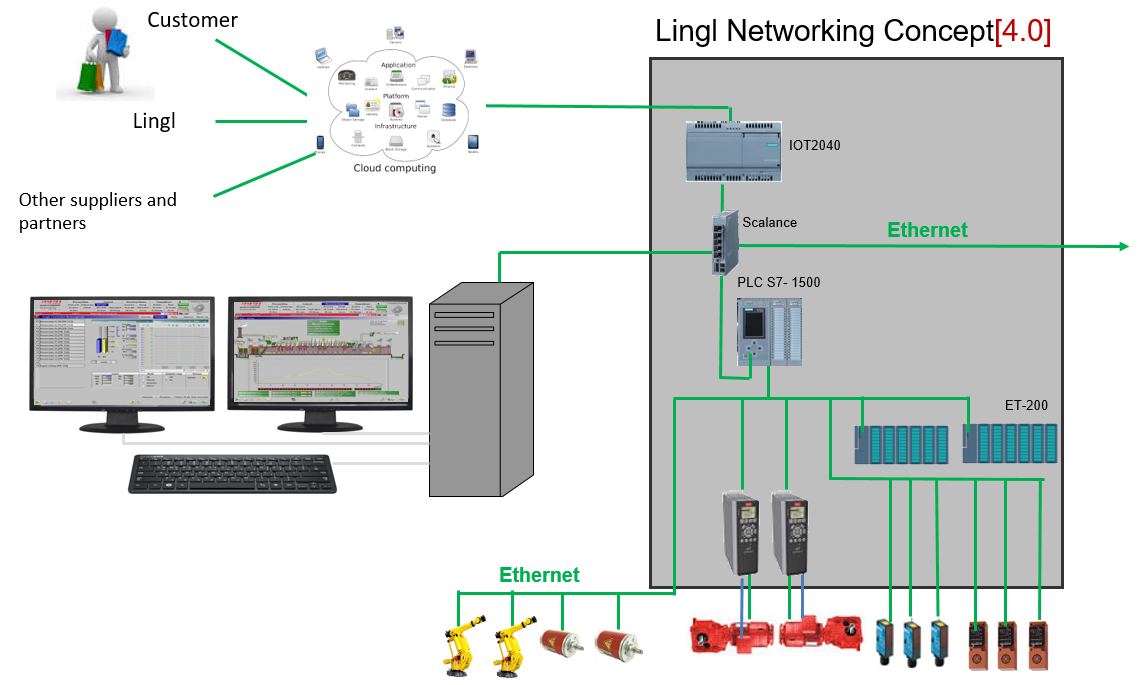

So in view of the complexity resulting from that it is our aim to make it manageable by networked and transparent production processes. Based on a smooth networking of all components, a consistent flow of information about the whole plant is achieved.

Intuitive operation via modern HMI systems allows to familiarize very quickly with the possibilities of computer-aided diagnosis for error identification. Consequently, the technical availability of the plant is increased and the machinery downtimes are reduced.

Adaptive user interfaces, production data acquisition and the virtual image of the machine in real time (digital twin) can be viewed at a central point, thus ensuring a consistent production overview.

Cloud-based storage systems enable an evaluation of the acquired data from a remote location, a consistent condition monitoring and thereby an analysis of the processes with regard to energy & production, in order to optimize both the quality and the quantity.

There is no general approach to the fourth industrial revolution. This trend rather describes a philosophy to use the digital revolution for the benefit of the own company and to build on existing strengths.

So let us define these approaches and implement them in your projects, in order to shape a successful future together with you.

„Let us start to produce smart“